How to Choose the Right Concrete Grinding Disc: A Complete Guide from Smoothing to Polishing

When it comes to concrete floor preparation, choosing the right grinding disc is crucial. The right grinding disc can significantly affect the construction progress and the overall treatment effect of the concrete floor. There are a variety of grinding discs on the market, and understanding their classification and application is essential to making an informed decision. This article will provide a comprehensive guide to help you choose the right concrete grinding disc for your specific needs, from leveling to polishing.

Common Types of Concrete Grinding Discs and Their Applications

1. PCD grinding wheel

Application: PCD discs are designed for the removal of thick epoxy coatings. They are particularly effective for coatings several millimeters thick.

Best use cases:

Heavy duty coating removal: Ideal for projects that require removing an old, thick coating before applying a new one.

Surface preparation: Ideal for preparing surfaces for further processing, ensuring a clean and even substrate.

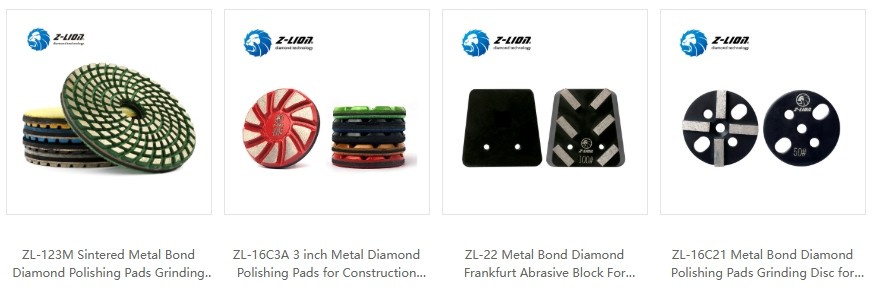

2. Concrete Diamond Grinding Pads

Application: These discs are widely used in levelling operations on concrete floors, as well as in the renovation of old floors.

Best use cases:

Levels uneven surfaces: Effectively smooths out bumps and bumps on concrete floors.

Restoration projects: Ideal for refurbishing old concrete surfaces that need a fresh start.

3. Thick concrete grinding disc

Application: Thick concrete grinding discs are over 5mm thick and contain diamond resin. Suitable for a variety of grinding tasks including leveling, coarse grinding, fine grinding and polishing.

Best use cases:

Coarse grinding: Suitable for the initial grinding stage where a large amount of material needs to be removed.

Fine grinding and polishing: Can be used in the later stages of the grinding process to obtain a smooth surface.

4. Thin concrete grinding disc

Application: Thin concrete grinding discs are less than 5 mm thick and are also made of diamond resin. Suitable for coarse grinding, fine grinding and polishing of concrete floors.

Best use cases:

Precision work: Ideal for projects that require a finer touch, such as fine grinding and polishing.

Surface preparation: Effectively prepare the final surface without removing excessive material.

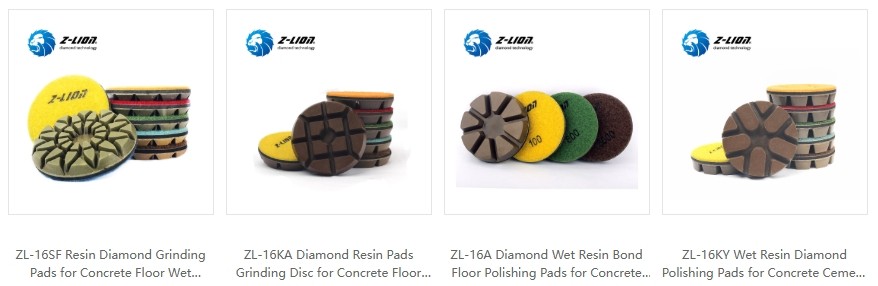

5. Concrete Polishing Pad

Application: Concrete polishing pads are made from a blend of man-made fibers, wool or other animal hair, and may contain abrasive and polishing additives. They are designed specifically for polishing concrete floors.

Best use cases:

Final polish: Ideal for achieving a high gloss finish on concrete surfaces.

Restores aesthetics: Helps enhance the visual appeal of concrete floors in commercial and residential settings.

How to Choose the Right Concrete Grinding Disc?

Selecting the right concrete grinding disc is essential to achieving the best results in your floor preparation projects. The right grinding disc not only affects the efficiency of the grinding process, but also the quality of the final surface. In order to make an informed decision, it is crucial to understand several core concepts related to concrete surface characteristics and grinding equipment.

1. Assess the flatness of the ground

The first step in selecting the right grinding wheel is to assess the flatness of the concrete surface to be machined. The surface conditions will determine the type of grinding wheel required:

Manually leveled or mechanically leveled floors: If the floor is loose or damaged, a high powered grinder with a high abrasive disc (such as a diamond concrete grinding disc) will be needed for effective leveling. These discs are designed to work with rough surfaces and can quickly remove material to achieve a level surface.

Self-leveling cement or mechanically polished floors: If the surface is well flat, polishing can be done using diamond resin polishing pads. These wheels are more durable and provide a nice finish without removing too much material.

2. Assess ground hardness

The hardness of the concrete surface is another key factor in choosing the right grinding wheel. While the grade of concrete can indicate strength, the actual hardness can vary depending on a number of factors. Here are ways to assess hardness:

Simple hardness test: Use a tool such as a nail or key to scratch the surface. If the surface is easily scratched, it means the hardness is less than 5. If the surface is not easily scratched, it means the hardness is greater than 5. This simple test can help you determine the appropriate type of grinding wheel.

Choose the right abrasive disc: For softer surfaces (hardness less than 5), you can choose a more impactful abrasive disc. For harder surfaces, you need a durable and efficient abrasive disc to avoid excessive wear.

3. Consider the weight and speed of the grinder

The type and size of grinder you use will also affect your choice of grinding disc:

Machine size: Floor sanders come in small, medium, and large sizes. Generally, larger machines are more powerful and more efficient. However, choosing a large machine is not always the best choice. An oversized sander will result in over-sanding, which will increase construction costs and may damage the floor.

Adjustment parameters: Experienced operators adjust the rotation speed, movement speed, number of discs and machine weight according to the specific characteristics of the machine and the surface to be treated. This optimization is essential to balance construction costs and efficiency.

4. Types and grit of grinding discs

PCD grinding wheel

Application: PCD discs are designed for removing thick coatings from concrete surfaces. They are especially useful for heavy duty applications where you need to remove old epoxy or other thick coatings.

Specific use: PCD diamond grinding wheels do not have a grit number, but their application is very specific. They are best suited for aggressive material removal and surface preparation.

Metal bond grinding discs

Application: Metal-based grinding discs are often used for pre-treatment and rough grinding of concrete floors. They can effectively level uneven surfaces and prepare for subsequent fine grinding.

Main features:

Grit classification: Metal abrasives are usually classified by numbers, such as 30#, 50#, 100# and 200#. The smaller the number, the coarser the abrasive. For example:

30#: Great for removing loose layers and leveling uneven surfaces.

50# or 100#: Suitable for achieving frosted or stone-ground effects.

Resin bond grinding discs

Application: Resin-based grinding discs are versatile and cover multiple steps in the grinding process, including coarse grinding, fine grinding and polishing. They are key to achieving a smooth polished result on concrete floors.

Main features:

Wide range of grit: Resin abrasive discs have a wide range of particle sizes, ranging from 30# to 3000#. Different particle sizes are usually marked with colored sticky cloth.

Hard resin discs: Better for flattening, typically used with medium to large grinders.

Soft resin discs: Polish more effectively and can be used with all types of grinders.

Understanding Granularity

The size of the diamond particles in an abrasive disc is critical in determining how efficient the disc is at a specific task. Here’s how to interpret the particle size:

Lower numbers: Indicates larger particles, more aggressive, suitable for initial grinding and material removal.

Higher numbers: Indicates smaller particles, providing a finer surface finish and used for polishing.

What Material Is the Floor I Want to Process?

When it comes to concrete floor preparation, understanding the material being treated is crucial to selecting the appropriate grinding disc. The hardness, condition and type of concrete can significantly impact the choice of tools and techniques used in the grinding process.

Evaluate floor hardness

A simple test can help you initially determine the hardness of your concrete floor. Here’s how:

Scratch test: Scratch the floor surface with your fingernail or key. If the tool does not leave a mark or scratch the surface, the concrete is likely harder. Conversely, if it scratches easily, the floor is likely softer.

Recommendations based on hardness

1. Hard concrete floor:

Recommended discs: For hard concrete, soft metal discs and sharp resin discs are recommended. These tools are designed to effectively grind hard surfaces without causing excessive wear.

Machine settings: Increase the counterweight on the grinder to apply more pressure. Also, reduce the RPM and forward speed of the grinder to allow for better control over the grind.

2. Soft concrete floor:

Recommended discs: For softer concrete, hard metal discs and durable resin discs are recommended. These discs will accomplish the required material removal without causing excessive damage.

Machine settings: Increase the grinder's speed and advance rate to speed up the grinding process.

Solving common flooring problems

Many concrete floors, especially old ones, may have problems such as poor flatness, loose surface, and insufficient hardness. Here are some ways to effectively solve these problems:

Process for dealing with problematic floors

1. Use medium and large floor grinders: For floors with serious problems, medium and large grinders are more effective. They provide the power needed to handle tough situations.

2. Watering and drying: Before sanding, it is best to water the surface first and then place it in a cool place to dry. This will help reduce dust and improve sanding efficiency.

3. Preliminary grinding:

First step: Use 30# hard metal grinding wheel to remove loose surface layer and level the ground. This step is essential for preparing the surface for subsequent treatment.

Step 2: Use 100# medium-hard or soft metal grinding disc to enhance the flatness and basic hardness of the floor. These two steps will simplify the subsequent construction steps.

Renovating old concrete floors

When refinishing old concrete floors, a key question arises: Do we need to remove the existing coating? The type and thickness of the coating will determine the choice of grinding wheel.

Coating removal strategies

Thick coating: For thick coatings, please choose single edge PCD grinding discs. These discs are designed for aggressive material removal and can effectively remove thick coatings.

Medium to thick coating: Double-edged PCD grinding discs are recommended for medium to thick coatings. They balance efficiency and effectiveness for this type of work.

Thin coating: For thin coatings, 30# metal abrasive disc is appropriate. This option can remove the coating without over-grinding the underlying concrete.

In Conclusion

Choosing the right concrete grinding disc is essential to achieving the best results in your floor preparation project. By understanding the different types of grinding discs and their specific applications, you can make an informed decision that meets the needs of your project. Whether you are leveling, grinding, or polishing, choosing the right grinding disc can improve your efficiency and the quality of your final floor. With the right tools at your disposal, you can ensure a successful and satisfying concrete floor preparation experience.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.