Can artificial stone be polished?

Yes. Artificial stone can be polished and a smooth polished surface can be obtained.

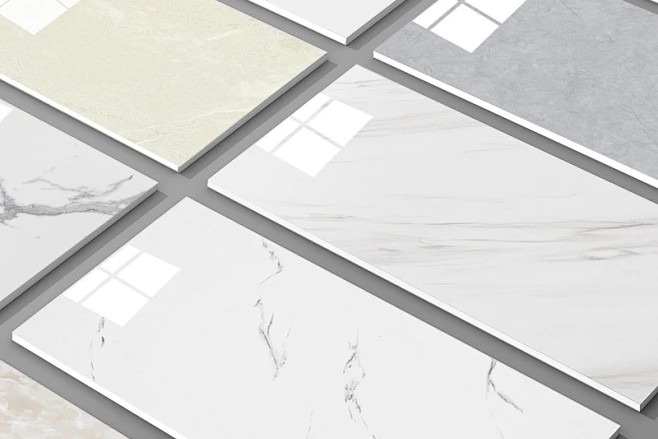

Engineered stone is a versatile and customizable material created by artificial methods that can be flexibly polished to achieve a smooth, lustrous surface. With the ability to adjust color, texture, and thickness to specific needs, engineered stone has become a popular choice in construction, home decoration, and various other fields. In this article, we’ll explore the concept of engineered stone, its benefits, and the polishing process for achieving a smooth, polished surface.

Learn About Artificial Stone

Artificial stone, as the name suggests, is a stone-like material made through artificial methods. This versatile material can be customized to meet specific requirements, with realistic textures, affordable pricing, and the ability to mimic the look of natural stone. Because of its flexibility in customization in terms of color, texture, and thickness, engineered stone is popular as a versatile and cost-effective alternative to natural stone in a variety of applications.

Artificial Stone Polishing Process

After the artificial stone is produced, it is polished to improve its aesthetics and surface quality. Polishing involves using abrasives to refine the stone surface and removing burrs and uneven areas from the surface to make it smoother and more visually appealing. This process is essential to achieve a bright, polished surface, making engineered stone suitable for a wide range of applications, including countertops, flooring, decorative elements, and architectural features.

Polishing Tools and Techniques: The tools used in the artificial stone polishing process include manual polishers, electric polishers, and various abrasives and polishing pads. These tools are essential in achieving the desired smoothness and glossiness of your stone surface. Different abrasives and polishing pads are used on polishing machines, allowing precise control and gradual refinement of the stone surface. Choosing the right tools and abrasives is critical to obtaining the best results and ensuring the quality of the finished surface.

Step-by-step polishing process: The engineered stone polishing process typically involves a series of steps, starting with the coarsest grinding discs and working your way up to the finest grinding discs. This progressive refinement eliminates surface imperfections and creates a smooth, uniform surface. Using different abrasives and polishing pads at each stage of the process helps achieve the desired smoothness and gloss, thereby improving the overall quality and visual appeal of the engineered stone.

Particle Grinding

Particle grinding is a meticulous process that involves gradually refining the surface, transforming it from rough and rough to smooth and shiny. As the abrasive grains change from coarse grinding to fine grinding and polishing, the wear marks on the surface of the stone gradually evolve, eventually showing a mirror-like luster and a dazzling appearance.

Rough grinding: In the initial stage, the grinding tool is required to have deep cutting depth and high grinding efficiency, resulting in rough grinding texture and surface. The focus of this stage is to remove saw blade marks, improve the flatness of the product, and lay the foundation for subsequent finishing.

Semi-fine grinding: The purpose of the semi-fine grinding stage is to remove rough grinding marks and form new, finer textures to make the product surface smooth and even. This stage helps to gradually refine the surface, preparing it for further polishing and enhanced shine.

Fine grinding: After fine grinding, the pattern, particles, and color of the product become visible, and the surface begins to show a delicate and smooth appearance with a light luster.

Ultra-fine grinding: The products processed at this stage have no traces visible to the naked eye, and the surface is smoother with a glossiness of about 40 to 50 degrees, which improves the overall quality and visual appeal.

Polishing: The final stage of particle grinding is to polish the surface to achieve a mirror-like gloss, with a certain mirror gloss exceeding 85 degrees. This stage helps enhance the aesthetics and durability of the surface, making it suitable for a wide range of applications.

The Effect of Artificial Stone Polishing

1. Enhance beauty and texture

The polishing process of artificial stone plays a vital role in enhancing its beauty and texture. By carefully polishing the surface, the polishing process results in a smoother, brighter, and more refined appearance, enhancing the overall visual appeal of the material. The transformation achieved by polishing not only enhances the beauty of the surface but also strengthens the hardness and texture of the stone, making its overall texture better and the visual effect more outstanding.

2. Enhanced hardness and durability

In addition to enhancing the aesthetics, the polishing process also enhances the hardness and durability of artificial stone. By refining the surface and eliminating imperfections, the polishing process helps improve the material's overall resiliency and longevity. The increased hardness and durability achieved through polishing make engineered stone suitable for a wide range of applications, including countertops, flooring, decorative elements, and architectural features, ensuring it can withstand the demands of a variety of environments and usage scenarios.

3. Advantages over natural stone

Artificial stone offers several advantages over natural stone, especially in terms of polish. Unlike natural stone, engineered stone does not have cracks and imperfections that can affect the polishing process and the overall visual appeal of the material. With no imperfections, polishing results are more consistent and reliable, resulting in a smoother, brighter, more refined surface that enhances the overall quality and visual appeal of the material.

4. Application and visual impact

The polished effect of artificial stone has a revolutionary impact on its visual appeal and suitability for a variety of applications. The smooth, lustrous surface achieved through the polishing process makes engineered stone suitable for countertops, vanities, floors, walls, and other architectural and decorative features. The enhanced beauty and durability of polished engineered stone make it a popular choice for residential and commercial projects, providing a cost-effective and visually appealing alternative to natural stone.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.