Diamond wire cutting technology

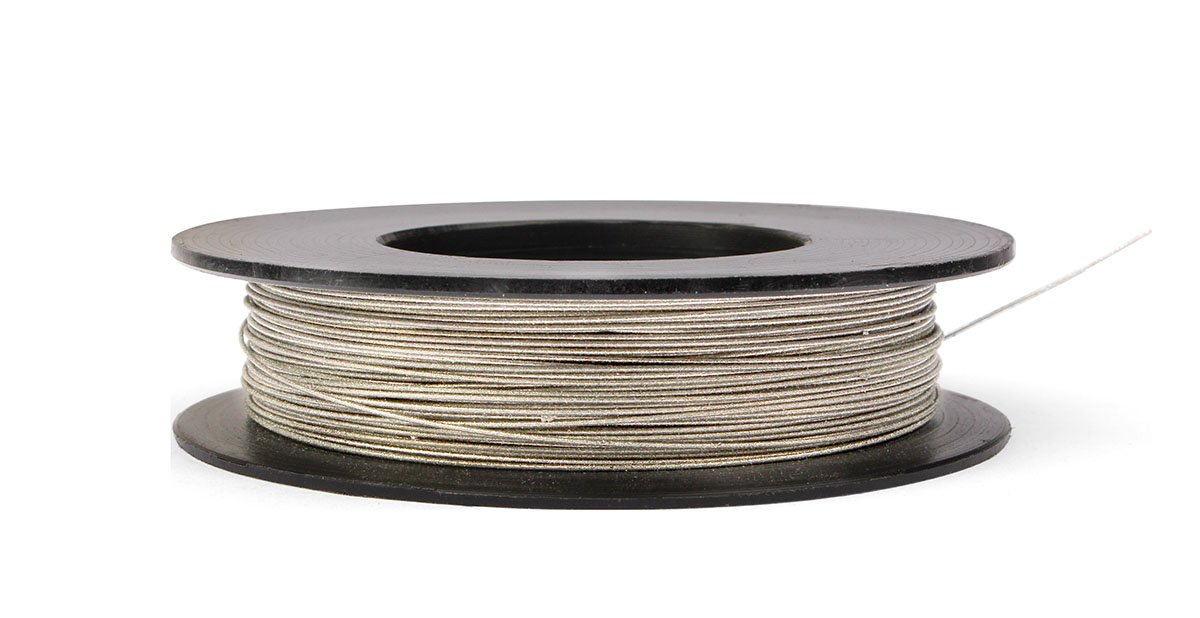

Diamond cutting wire is an important tool for the efficient cutting of hard and brittle materials in various industries. The wire is made by coating diamond particles onto steel wire using a specific method. This process creates a relatively abrasive motion that allows the wire to cut through even the toughest materials. The diamond wire consists of consolidated abrasive diamond saw wire, made by the composite electroplating method. This method consolidates high hardness and high wear resistance diamond powder onto a steel wire matrix. The cutting process of diamond wire is highly dependent on the strength and quality of the steel wire as 90% of its tensile strength comes from the steel wire. In the construction industry, diamond-cutting wires are an important tool for creating clean cuts in reinforced concrete.

Likewise, in the electronics industry, diamond dicing wires are used to cut sapphire wafers, which are key components in various electronic devices. It is also used in the automotive and aerospace industries for cutting composites, ceramics, and other hard materials.

The unique properties of diamond cutting wire make it an efficient tool for cutting hard materials while minimizing waste. The diamond particles on the surface of the wire provide a sharp and precise cutting edge that can withstand high temperatures and pressures without losing their sharpness or shape. To ensure the high performance of the diamond cutting wire, manufacturers pay attention to the quality of the diamond particles used in the production process. Using diamond powder with high hardness and high wear resistance ensures the long-lasting performance of the wire and helps reduce production costs in the long run.

To sum up, diamond cutting wire is an important tool for the efficient cutting of hard and brittle materials in various industries. The quality of steel wire is very important, and the strength and quality of steel wire are the key factors to be considered in the production process. The unique properties of diamond cutting wire make it an efficient and cost-effective precision cutting tool. As technology advances, we can expect diamond wires to play an increasingly important role in manufacturing.

Diamond cutting wire has three advantages over traditional crafts:

Compared with traditional cutting methods, diamond wire cutting has the advantages of less leakage loss, long service life, fast cutting speed, high cutting efficiency, and improved production capacity.

The precision and consistency of diamond wire cutting provide higher output quality while reducing production costs. In addition, the damage layer caused by the cutting process is smaller than that of traditional mortar wire cutting. This makes diamond wire dicing advantageous for cutting thinner silicon wafers.

Furthermore, environmental concerns are an important aspect of the production process. Diamond cutting wire is one of the few cutting options available with environmentally friendly technology. Diamond wire uses a water-based abrasive, mainly water. This makes the cutting process less dangerous, improves the working environment, and simplifies cleaning procedures.

Given these advantages, it's no surprise that diamond wire cutting is gaining popularity across several industries. The efficiency, precision, and eco-friendliness of diamond wire cutting are key factors in a dynamic production process that ensures maximum yield while reducing pollution. This makes it an excellent choice for companies looking to improve their processes and reduce their ecological footprint.

Why can diamond wire improve efficiency?

Diamond wire cutting adopts a consolidation method, allowing more diamonds to participate in the cutting process, and improving the accuracy and speed of cutting materials. This method also helps to reduce mutual wear between abrasives, thereby reducing workpiece errors. One of the main reasons for the higher efficiency of diamond wire cutting is due to the high hardness and wear resistance of diamonds. This high durability ensures that the diamond wire has an extended life, reducing costs associated with regular replacement and maintenance.

Another factor that contributes to the efficiency of diamond wire cutting is its high cutting wire speed. The high cutting speed of the diamond wire increases the contact area between the diamond wire and the material being cut, resulting in faster and more precise cutting. Despite the high wire speed, the diamond wire can withstand other potential disadvantages of this speed, ultimately maximizing the advantages of high cutting speed.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.