Introduction to Diamond Wire Cutting: A Highly Efficient and Precise Gemstone Cutting Tool

Diamond wire cutting technology has become a revolutionary technology in the stone cutting industry, characterized by high efficiency and high precision. This method utilizes a high-speed rotating diamond wire cutter to cut various types of stone, making it ideal for large-scale and complex stone processing. This article will explore the principles, advantages, and wide applications of diamond wire cutting in the stone industry.

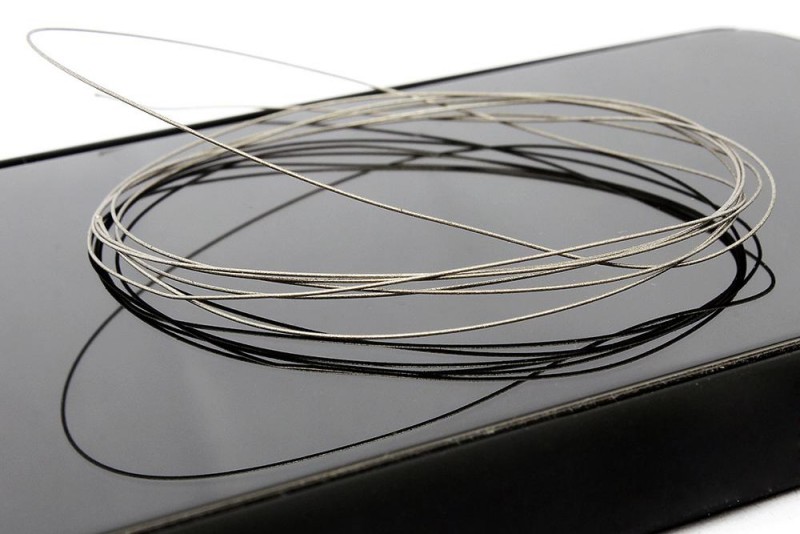

Principle of Diamond Wire Cutting

The principle of diamond wire cutting is relatively simple yet highly effective. A diamond wire consists of a thin steel wire with attached diamond particles, which rotates at high speed and rubs against the surface of the stone. This friction generates a large amount of heat, causing the stone to reach its melting point and eventually break.

This method is particularly suitable for cutting larger stones because it allows for fast and efficient cutting while minimizing damage to the stone surface. By controlling the cutting angle and depth, cutting precision can be further improved, enabling the creation of complex shapes and designs.

Advantages of Diamond Wire Cutting

Compared with traditional stone cutting methods, diamond wire cutting has the following significant advantages:

High cutting precision:

One of the most significant advantages of diamond wire cutting is its ability to cut at any angle and cross-section without damaging the stone surface. This high precision is crucial for applications requiring complex designs and tight tolerances, such as architectural components and decorative stone.

High-speed cutting:

Diamond wire cutting is renowned for its rapid cutting capabilities. This method completes stone cutting tasks in significantly less time, dramatically improving work efficiency. This speed advantage is particularly pronounced in time-critical business environments.

Wide applicability:

Diamond wire cutting can be used to cut stones of various hardness and thickness, making it a widely used tool in the stone industry. Whether processing soft materials such as limestone or hard stones such as granite and marble, diamond wire cutting can efficiently process complex shapes, making its applications extremely broad.

Diamond Wire Cutting Instructions

1. Prepare the stone surface

Dry and smooth surface: Before cutting, ensure the stone surface is dry, smooth, and free of obvious cracks or deformation. A stable surface is crucial for accurate cutting and preventing damage to the stone.

Inspection: Conduct a thorough inspection of the stone to identify any potential defects that could affect the cutting process. If any issues arise, resolve them before proceeding with cutting.

2. Choose the appropriate diamond thread

Diameter and length: Select the appropriate diameter and length of diamond wire based on the specific cutting requirements. The diameter should match the gemstone type and the required cutting depth.

Threading: Carefully thread the diamond wire through the pulley traction system, ensuring it is properly aligned and secured. This step is crucial for smooth operation during the cutting process.

3. Adjust the cutting depth

Tension control: The cutting depth is adjusted by controlling the tension of the cutting wire. Appropriate tension is crucial for achieving the desired cutting depth and ensuring the cutting wire functions effectively while avoiding excessive wear.

Calibration: If necessary, calibrate the cutting system to ensure that the cutting line is set to the correct depth for the specific gemstone being cut.

4. Begin cutting

Slow rotation: While controlling the cutting speed and angle, slowly rotate the cutting line. Start slowly so that the cutting line can effectively contact the stone.

Monitor cutting progress: Closely monitor the cutting process and adjust the cutting speed and angle as needed. Continuous monitoring helps maintain cutting accuracy and prevents damage to the stone.

5. Clean the stone surface

Post-cutting cleaning: After cutting, thoroughly clean the stone surface to remove any remaining metal wires or debris. This step is crucial to prevent residue from causing cracks or imperfections in the stone.

Final Inspection: Perform a final inspection on the cut surfaces to ensure they meet the required quality standards.

Applications of Diamond Wire Cutting

Diamond wire cutting is suitable for a variety of applications in the stone industry. Its versatility allows it to be used to cut various types of stone, including:

Marble and granite: Ideal for countertops, tiles, and decorative elements in residential and commercial spaces.

Sandstone and bluestone are commonly used for exterior walls, landscape features, and architectural details.

Limestone: Commonly used for building exterior walls, floors and other structural components.

In addition to the applications mentioned above, diamond wire cutting is also widely used in the construction of buildings such as villas, hotels, apartments, shopping malls, and plazas. Its ability to achieve clean, precise cuts makes it the preferred choice for large projects and complex designs.

In Conclusion

Diamond wire cutting represents a significant advancement in stone cutting technology, far surpassing traditional methods in efficiency and precision. It enables complex cuts without damaging the stone surface, and its high cutting speed and wide range of applications make it an indispensable tool in the stone industry. As market demand for high-quality stone products continues to grow, diamond wire cutting is expected to play an increasingly important role in meeting these demands and improving the efficiency and quality of stone processing.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.