What fields can diamond sanding belts be used in?

Electroplated Diamond Sanding Belts: Characteristics and Applications

Electroplated diamond sanding belts are innovative processing tools that revolutionize the way materials are ground, ground, and polished. By electrochemically attaching diamond particles to copper or nickel metal belts, these abrasive belts offer a range of advantages that make them ideal for a variety of industrial applications.

Characteristics of electroplated diamond sanding belts

1. Advanced bonding technology

The electroplating process used to attach the diamond particles to the metal substrate ensures a strong bond, thereby enhancing the durability and performance of the sanding belt. This advanced technology creates conveyor belts that can withstand high levels of wear, making them suitable for demanding applications.

2. Versatile grit option

Electroplated diamond sanding belts are available in a variety of grit sizes, from coarse to very fine. This versatility allows users to select the right conveyor belt for their specific application, whether they require powerful material removal or delicate surface treatment.

3. Stable performance

The diamond particles are evenly distributed over the surface of the abrasive belt, ensuring consistent performance throughout its service life. This feature is critical for achieving high-quality finishes and maintaining precision in a variety of applications.

4. Reduce clogging

One of the significant advantages of electroplated diamond sanding belts is their resistance to clogging. Unlike traditional abrasive belts, which can become clogged with debris, electroplated sanding belts maintain their cutting efficiency, allowing for uninterrupted operation and reduced downtime.

5. High processing speed

Electroplated diamond sanding belts are designed for high-speed applications and can remove material faster than traditional sanding methods. Increased efficiency can significantly save time in the production process.

6. Low heat generation

The efficient cutting action of the diamond particles minimizes the heat generated during operation. This feature is particularly useful when working with heat-sensitive materials, as it helps prevent deformation or damage.

Application of electroplated diamond sanding belt

1. Grinding application

a.Hard material removal

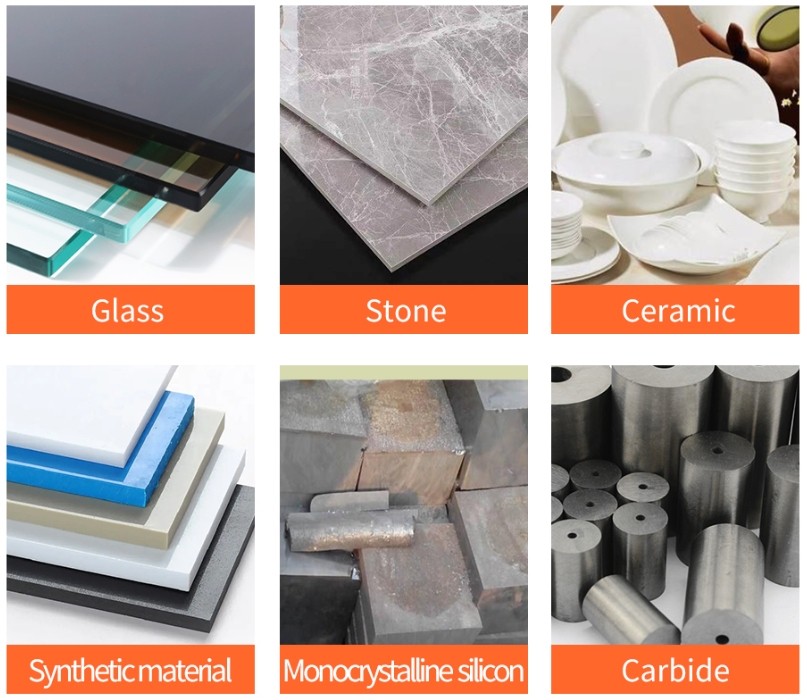

Electroplated diamond sanding belts excel in grinding applications due to their superior cutting properties. They are particularly effective at removing hard materials such as:

Ceramics: Diamond’s high hardness can effectively grind ceramic parts, which are often challenging to machine.

Glass: These belts grind glass surfaces smoothly, making them ideal for glass industry applications.

Stone: Electroplated diamond sanding belts are widely used for shaping and finishing stone surfaces, providing a high-quality finish.

Additionally, their durability makes them suitable for grinding tool materials including:

Carbide: Carbide is commonly used in cutting tools that require specialized grinding techniques that electroplated diamond belts can provide.

Tool steel and high-speed steel: These materials benefit from the efficient material removal capabilities of diamond abrasive belts, ensuring tool manufacturing accuracy and longevity.

b.Surface treatment

In the field of grinding, electroplated diamond abrasive belts can effectively remove burrs, scratches, and uneven parts on various surfaces. This application is essential for:

Metal surface: Sanding belts can grind metal surfaces to obtain a smooth, bright surface, thereby improving the aesthetic and functional qualities of the final product.

Composites: They are also used to prepare composite surfaces, ensuring uniformity and readiness for subsequent processing steps.

2. Polishing application

Electroplated diamond sanding belts play a vital role in the polishing process and achieving a perfect surface finish is essential. Their applications in polishing include:

a.Smooth surface

During the polishing process, these sanding belts effectively remove microscopic defects on the material surface, resulting in a smoother surface. This feature is particularly beneficial for industries that require a high-quality surface finish, such as:

Glass polishing: Electroplated diamond sanding belts are widely used to polish glass products, ensuring clarity and smoothness.

Gemstone finishing: In the jewelry industry, these bands are used to achieve the luster and finishing required of gemstones, enhancing their visual appeal.

Optics: The precision provided by electroplated diamond abrasive belts is critical for polishing optics, where even the slightest imperfections can affect performance.

b.Final touches

In many manufacturing processes, electroplated diamond abrasive belts are used for final polishing. Their ability to provide a high-gloss finish makes them ideal for applications where aesthetics are as important as functionality.

In summary, electroplated diamond abrasive belts are an indispensable tool in a variety of applications, especially when grinding and polishing hard materials. Its superior cutting performance, durability, and ability to produce high-quality finishes make it the first choice in industries such as ceramics, glass, metalworking, and jewelry. As technology continues to advance, the versatility and efficiency of electroplated diamond abrasive belts may lead to a wider range of applications, further enhancing their role in modern manufacturing processes.

Resin Diamond Sanding Belts: Characteristics and Applications

Resin diamond sanding belts are advanced processing tools that combine the durability of resin with the cutting efficiency of diamond particles. This unique composition makes them highly effective for a variety of applications across multiple industries.

Characteristics of resin diamond sanding belts

1. Durable resin bonding

The resin used in these sanding belts provides a strong bond to the diamond particles, ensuring they remain firmly attached during operation. This durability allows the belt to withstand high levels of wear, making it suitable for demanding applications.

2. Versatile grit option

Resin diamond sanding belts are available in a variety of particle sizes, from coarse to fine. This versatility enables users to select the right conveyor belt for their specific needs, whether they require powerful material removal or a smooth finish.

3. Stable performance

The uniform distribution of diamond particles on the surface of the resin tape ensures consistent cutting performance throughout its lifetime. This feature is critical for achieving high-quality finishes and maintaining precision in a variety of applications.

4. Heat resistance

Resin diamond sanding belts exhibit excellent heat resistance, which is crucial when working with materials that are sensitive to temperature changes. This feature helps prevent workpieces from being deformed or damaged during grinding or polishing.

5. Reduce clogging

These belts are designed to minimize clogging, allowing for uninterrupted operation. The efficient cutting action of diamond particles helps keep surfaces free of debris, thereby increasing productivity.

Application of resin diamond sanding belt

1. Grinding application

Resin diamond sanding belts are widely used in grinding applications due to their ability to effectively remove material from hard surfaces. They are particularly effective for:

Metal: These abrasive belts can grind a variety of metal surfaces, providing a smooth and polished finish.

Ceramics and glass: Their high hardness makes them ideal for grinding ceramics and glass, which are often challenging to process.

2. Grinding and finishing

In abrasive applications, resin diamond sanding belts are used to achieve precise surface finishes. They provide a consistent and smooth surface, making them suitable for:

Optical components: Using resin diamond tape can meet the precision required for optical manufacturing, ensuring a high-quality surface.

Jewelry: In the jewelry industry, these strips are used to achieve the desired shine and finish on various materials.

3. Polishing application

Resin diamond sanding belts are also effective during the polishing process. They remove microscopic imperfections from a material's surface, resulting in a smoother surface. Common applications include:

Glass polishing: These strips are widely used for polishing glass products, ensuring clarity and smoothness.

Gemstone finishing: In the field of jewelry, resin diamond bands are used to enhance the visual appeal of gemstones by providing a high-gloss finish.

4. Composite materials processing

Resin diamond sanding belts are increasingly used in the processing of composite materials. Their ability to grind and polish these materials without causing damage makes them valuable in industries such as aerospace and automotive.

In summary, resin diamond sanding belts are versatile, efficient tools that offer numerous advantages for grinding, grinding, and polishing applications. With durable resin bonding, consistent performance, and the ability to minimize clogging, these belts are ideal for a variety of materials including metals, ceramics, glass, and composites. As the industry continues to demand higher precision and quality, resin diamond abrasive belts will play an increasingly important role in meeting these demands, making them an essential tool in modern manufacturing processes.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.