What grit sandpaper to use to polish marble?

Principles for Choosing Sandpaper Grit

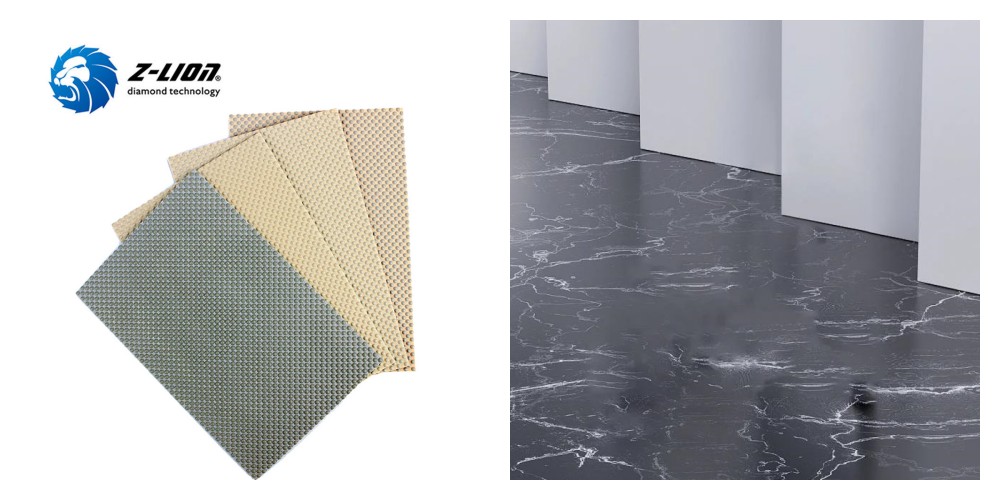

Choosing the right marble sandpaper grit is a critical step in getting the best results when polishing marble surfaces. The grit of the sandpaper plays a vital role in determining the degree of grinding and the quality of the polishing effect. Understanding the principles of selecting a sandpaper grit is critical to achieving a smooth, flawless finish while maintaining the integrity of your marble surface. By following these principles, an individual can effectively refine a marble surface and achieve the desired level of polish.

The higher the mesh number, the finer the sandpaper. When choosing sandpaper for marble polishing, it is important to consider the specific situation and desired results. As a general principle, the grit size of the sandpaper should be selected based on the initial condition of the marble surface and the degree of refinement required.

In practice, it is recommended to start with coarser sandpaper and then move to finer mesh sizes. Coarse sandpaper is effective at addressing initial imperfections, uneven surfaces, or rough areas on marble. By initially using coarser sandpaper, one can effectively smooth the surface and remove any prominent imperfections, preparing the marble for subsequent polishing steps.

As the polishing process progresses, you must gradually transition to a finer sandpaper to achieve the desired polishing effect. Finer mesh sizes are effective at further refining surfaces, resolving minor imperfections, and achieving a smooth, consistent finish. By using finer sandpaper, one can enhance the overall beauty and visual appeal of the marble, resulting in a polished surface that showcases the stone's natural beauty.

What Grit Sandpaper for Marble?

1. Primary polishing:

During the initial stages of polishing, it is recommended to use sandpaper with a grit of 120 to 400. The focus of this stage is to remove surface dirt and imperfections to get to the starting point of the polishing process. Coarse sandpaper, such as 120-grit sandpaper, is effective at addressing initial imperfections and preparing the surface for subsequent polishing steps. As the primary polishing stage progresses, finer sandpaper (such as 400-grit sandpaper) can be used to further refine the surface and prepare it for intermediate polishing.

2. Middle polishing:

In the intermediate polishing stage, it is recommended to use sandpaper with a grit of 600 to 2000. This stage is the focus of the polishing process, where the surface is refined to achieve a smooth, consistent finish. It should be noted that each grit of sandpaper should be used evenly and should not be sanded repeatedly to ensure consistent and effective sanding results. By gradually transitioning from coarser to finer sandpaper, an individual can effectively refine the surface and achieve the desired smoothness and gloss.

3. Advanced polishing:

For advanced polishing and a finer surface shine, it is recommended to use sandpaper with a grit of 2000 or above. The focus of this stage is to achieve a high level of polish and enhance the overall aesthetics of the surface. If a high level of surface gloss is required, metal abrasive paste or polish can be used to further refine and clean the surface to achieve a superior level of polish and visual appeal.

In summary, sandpaper mesh selection is a key consideration in achieving a smooth, flawless finish when polishing a variety of surfaces. By using appropriate mesh sizes during the primary, intermediate, and advanced stages of polishing, an individual can effectively refine the surface and achieve the desired level of polish, thereby increasing the overall beauty and value of the surface.

Precautions

When undertaking the polishing process, certain precautions must be observed to ensure successful and effective results. These precautions are designed to maintain a clean and safe working environment, achieve high-quality surface finishes, and optimize the polishing process. By adhering to these precautions, individuals can minimize the risk of contamination, address surface imperfections, and achieve the desired level of polish. Here are some important precautions to consider:

1. Protect the surrounding environment:

During the polishing process, it is crucial to protect the surrounding environment to prevent sand and other impurities from contaminating the room. This can be achieved by using shields, barriers, or containment measures to minimize the spread of dust and debris. By maintaining a clean and controlled environment, individuals can minimize the risk of contamination and ensure the polishing process runs smoothly and efficiently.

2. Pay attention to details:

Special attention should be paid to details such as burrs and surface imperfections to ensure a high level of cleanliness and consistent polishing results. Addressing these details is critical to achieving a smooth, flawless surface, as surface imperfections can affect the overall quality of the polish. By carefully inspecting the surface and addressing any imperfections, an individual can achieve a high-quality finish and enhance the overall beauty of the polished surface.

3. Avoid a rushed polishing process:

It’s important to strike a balance between shorter application time and improved polish. Excessive application time will affect the quality of the polish because the polishing effect is not simply related to the thickness of the sandpaper used. By taking the time to carefully complete the polishing stages and ensuring each step is completed thoroughly, an individual can achieve a high-quality finish and optimize the overall efficiency of the polishing process.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.