Three minutes to understand what cutting blade to use for cutting tiles

Cutting tile can be a challenging task, but with the right tools and techniques, it can be a breeze. Whether you're an experienced DIYer or a professional contractor, knowing the proper steps for tile cutting is crucial.

First and foremost, choosing the right cutting machine for the job is critical. For most tile-cutting projects, a handheld angle grinder or a cutter purchased from a hardware store will suffice. After choosing a machine, the next step is to accurately measure and mark the tiles. Use a tape measure to determine the required size and mark the tiles accordingly. To enhance your cutting experience and extend the life of your saw blade, it is highly recommended to add water while cutting. This serves two purposes - reducing dust particles flying around and controlling the temperature of the blade. By adding water, the blade is prevented from overheating, thereby reducing the risk of deformation and improving cutting accuracy.

To cut square holes in tile, a portable disc cutter with a cutting blade is your tool of choice. Begin by marking square holes on the surface of the tile. Then, using a portable disc cutter, cut along the lines on the back of the tile. This technique ensures that the tile surface remains intact while achieving the desired square holes. When cutting round holes, follow a similar approach with a tile cutter mounted on a portable disc cutter. Start by marking a cross in the middle of the back of the tile. Then, cut along the cross from the back, creating a starting point. From there, you can finish the round hole by cutting the face of the tile.

When using a cutting machine, the cutting blade must be installed correctly and the cutting depth adjusted to the desired size. Place the tile on a stable work surface and make sure it is firmly in place. Once everything is set, start the cutting process, making sure to follow the marked lines exactly. For cutting cultured marble, the same principle applies. Lay the marble flat, measure the desired size with a ruler, and draw the cutting lines. Attach the stone cutting blade to the cutter and cut along the marked line in a slow but steady motion. Stay hydrated by adding water to the mineral water bottle if needed to ensure optimal cutting efficiency.

By following these techniques, you'll be well-equipped to tackle any tile-cutting project. Remember to make safety a priority by wearing proper protective gear like goggles and gloves. By mastering the art of tile cutting, you'll achieve professional-quality results that will leave your surfaces looking flawless and perfectly fitted.

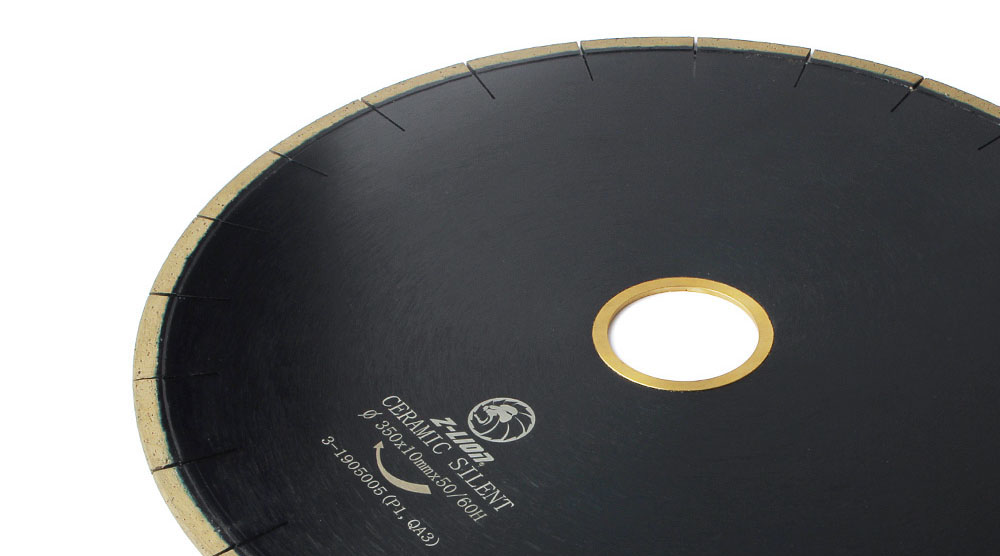

Ceramic tile cutting blade generally have the following properties:

1. Even mixing: In order to maintain the consistency and uniformity of the tile cut pieces, it is essential to ensure that all materials are thoroughly mixed. This promotes a uniform distribution of the particles and improves the overall structure of the sintered body of the saw blade.

2. Control feeding amount: Accurate calculation of theoretical density and precise control of feeding amount are very important to achieve the required compactness of tile cutting pieces. This ensures that the blade has the strength and durability needed to cut tile effectively.

3. Pre-alloyed powders: Adding pre-alloyed powders to the formulation helps improve the performance and performance of tile-cutting discs. It increases hardness, toughness, and wear resistance for more reliable cutting tools.

4. Choice of process: Different cutting materials and saw blades require specific processes to achieve the best results. For tile saw blades, the hot pressing sintering process is often selected. This involves applying heat and pressure to consolidate the material and produce a dense blade with excellent cutting ability.

5. High-quality fine grain corundum: Corundum is an abrasive material commonly used for tile cut pieces. Choosing a high-quality, fine-grained emery will ensure that the cutting piece will effectively cut through the tile with high precision and minimal splintering.

-

Online service

-

Official wechat

account

-

QQ:40933769

-

E-mail:

sales@z-lion.com

Online service

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.